News

Single-Eye Anchor Requirements

‘Anchor Points’, ‘Roof Anchors’, ‘Fall-Restraints’, ‘Sky Hooks’… They go by many names, but what do you need..

By Lewis Liles 23 October 2025

‘Anchor Points’, ‘Roof Anchors’, ‘Fall-Restraints’, ‘Sky Hooks’… They go by many names, but what do you need..

By Lewis Liles 23 October 2025—

This Height Safety guide explains Single‑Eye Anchors within a broader Roof Access System context — what changed in AS 5532:2025 and AS/NZS 1891.4:2025, and how to verify, install, and maintain compliant roof anchors with ongoing Inspections and Certifications.

—

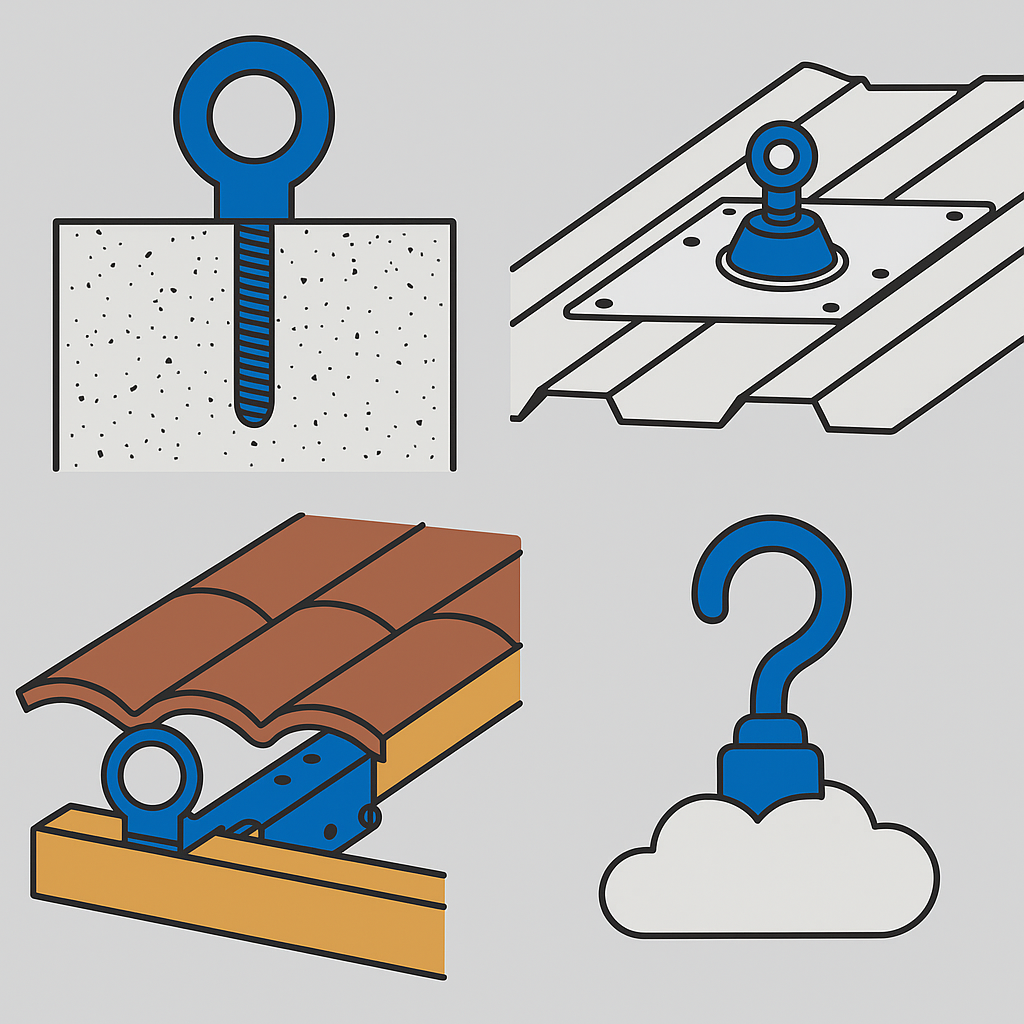

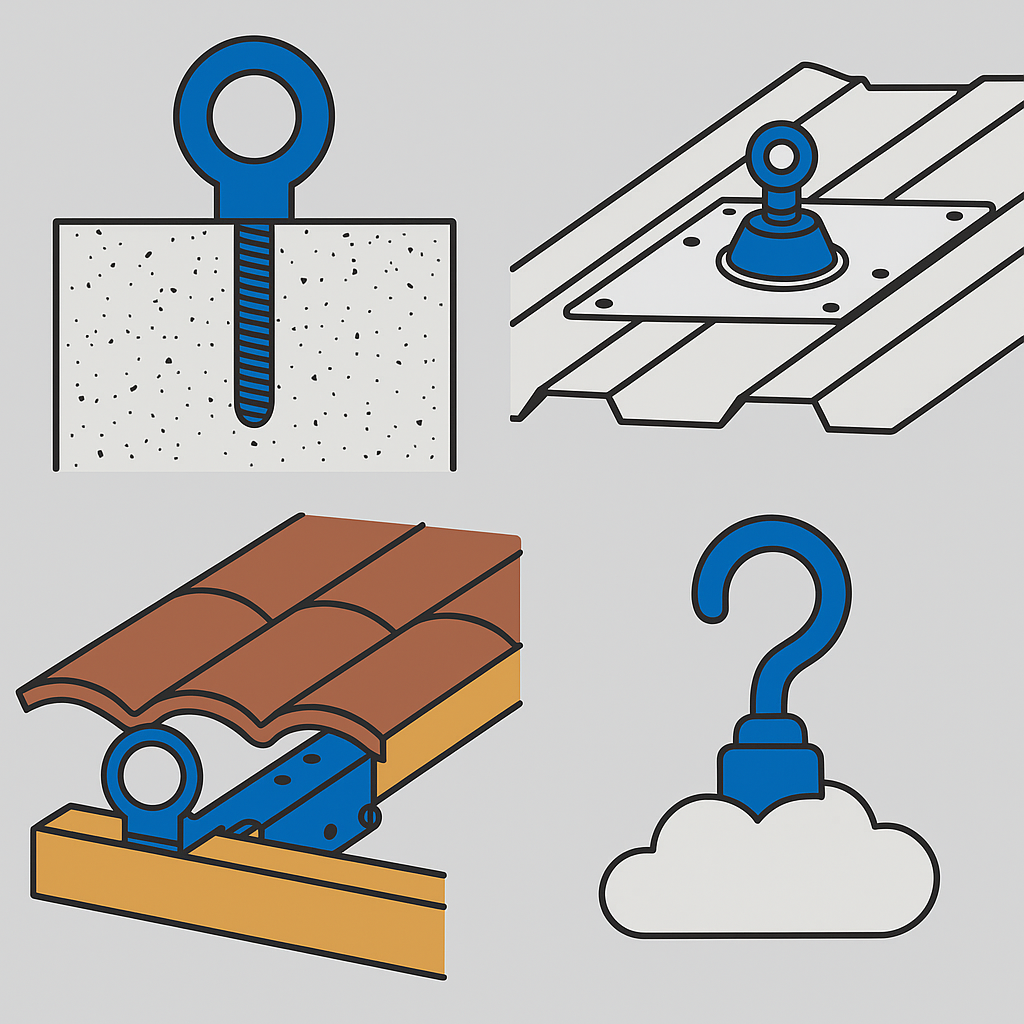

WHAT IS A SINGLE‑EYE ANCHOR?

A Single‑Eye Anchor — also known as a Single‑Point Anchor, Roof Anchor, or Anchor Point — is a designated attachment point fixed back to a supporting structure (such as steel, concrete, or timber) that is engineered, tested, and installed to withstand the prescribed forces defined in AS 5532 for personal fall‑arrest or restraint systems.

In simple terms, it’s the connection point between a worker’s fall‑arrest equipment (such as a harness and lanyard) and the building structure. Its job is to arrest or restrain a fall by transferring the load safely into the structure without failure.

– Permanently or temporarily fixed to a structural member.

– Tested dynamically and statically to specified load levels (typically 12 kN – 21 kN, depending on classification).

– Clearly marked, traceable, and supplied with installation and maintenance documentation.

– Intended for personal attachment only, not for lifting or material handling.

Explore our Systems page for Anchor Points.

—

THE STANDARDS THAT GOVERN ANCHORS

Australia’s Height Safety framework relies primarily on two complementary standards that underpin any robust Fall-Restraint or Fall Arrest System:

AS 5532:2025 — Design, manufacture, and testing of single‑point anchors for personal fall‑arrest systems.

AS/NZS 1891.4:2025 — Selection, installation, use, and maintenance of fall‑arrest systems and components.

If you require assistance verifying an existing Height Safety System or designing a new approach to your workers safety, you can get in touch now.

—

WHY THE STANDARDS WERE UPDATED

– Old lab setups didn’t always reflect real‑world substrates.

– Confusion between energy‑absorbing and static anchor testing.

– Ambiguity in marking and traceability.

– Overlap with AS/NZS 1891.4 created inconsistent compliance claims.

The 2025 revisions align testing methods, clarify responsibilities, and increase transparency from manufacturing to installation — improving Height Safety outcomes across all industries.

—

WHAT’S NEW IN AS 5532:2025

1) Clear Classifications and Load Ratings

– 12 kN — Limited free‑fall, single‑user anchor.

– 15 kN — Standard fall‑arrest anchor for one user.

– 18 kN — Limited free‑fall anchor for two users.

– 21 kN — Full fall‑arrest anchor for two users.

2) Realistic Substrate Testing

– Dynamic Drop Test — simulates a fall to measure energy absorption.

– Function Test on Actual Substrate — performed on the roof or structure type the anchor is designed for.

– Static Load Test — confirms sustained load performance after the drop test.

3) Improved Marking & Documentation

– Manufacturer name/logo, serial or batch number.

– User rating and load capacity.

– Compliance statement: “Complies with AS 5532:2025”.

– Installation and maintenance instructions supplied.

4) Design Guidance & Environmental Factors

– Anchor spacing and positioning in a Roof Access System.

– Substrate and fastener selection.

– Corrosion resistance and material selection.

– Compatibility with lanyards and energy absorbers.

—

WHAT’S NEW IN AS/NZS 1891.4:2025

– Alignment with AS 5532 to prevent overlap.

– Revised inspection intervals and record‑keeping for Periodic Inspections.

– Clearer competency expectations for installers and inspectors.

– Guidance for rope angles, diversion anchors, and secondary connections.

– Improved guidance for rescue planning and fall‑clearance calculations.

Need confirmation that your existing anchors are still compliant? Book an Audit of your site or system.

—

PUTTING COMPLIANCE INTO PRACTICE

Verify Certification

Request independent certificates that confirm AS 5532:2025 compliance, and for friction‑fit anchors you must ensure on‑site Proof Loading to validate installation performance.

Confirm Markings & Documentation

Ensure each anchor is clearly labelled as AS 5532:2025 compliant; record batch/serials in your asset register.

Use Competent Installers

Only suitably trained persons should install or certify anchors, verifying structural adequacy and creating as‑built records. That’s why we’re partnered with Kattsafe (formerly SAYFA GROUP) to ensure we have the correct products and knowledge when designing and installing height safety and roof access systems.

Maintain & Inspect Annually

Schedule Periodic Inspections at least every 12 months (more often in corrosive environments). We assist in documenting the condition, label legibility, corrosion, and fasteners associated with anchors used for harness-based work. This ensures ongoing compliance and peace of mind.

—

TRANSITIONING FROM AS 5532:2013 TO AS 5532:2025

Legacy anchors aren’t automatically obsolete, but the new standard raises the bar. At your next inspection, review existing anchors against 2025 expectations, verify documentation and markings, and upgrade if uncertain. As required, you must still Proof Load to validate friction‑fit anchors.

—

LEGAL & WHS CONSIDERATIONS

Australian Standards are not laws, but they’re referenced in WHS Regulations and the Falls Code, making them the recognised benchmark for what’s “reasonably practicable.” Compliance supports due diligence for PCBUs and duty holders within a Height Safety management plan.

—

COMMON NON‑CONFORMANCES

– Anchors on untested or inadequate substrates.

– Missing or illegible markings.

– No traceable installation or inspection record.

– Overdue Periodic Inspections (https://ehsafety.com.au/services/test-and-inspection/).

– 2013‑tested anchors still marketed as “5532‑compliant” without 2025 evidence.

—

FAQ

Are existing AS 5532:2013 anchors still valid?

Yes — if properly tested, installed, and maintained — but reassess against 2025 criteria at the next inspection. Consider an independent Audit.

Can a fall-arrest anchor claim compliance with AS/NZS 1891.4 instead of AS 5532?

No. AS 5532 covers anchor manufacture and testing; AS/NZS 1891.4 governs selection and use.

How often should anchors be inspected?

At least annually, and more frequently in high‑use or corrosive environments — schedule your Periodic Inspections (https://ehsafety.com.au/services/test-and-inspection/).

What’s the difference between fall‑arrest and restraint systems?

Fall‑arrest stops a fall already in motion; restraint prevents access to the fall hazard. Both can be integrated into a Roof Access System using compliant Anchor Points (https://ehsafety.com.au/systems/anchor-points/).

If you allow workers Roof Access to your building, you have a legal obligation to comply with all Australian Standards, Codes and Regulations around Height Safety, Roof Safety, Fall Protection and Fall Arrest. To ensure the Height Safety of your workers and the legal compliance for your business, contact the trained and accredited experts today for an obligation free consultation.

ENQUIRE NOWThe Sayfa Group have partnered with Essential Height Safety as Australia’s leading specialist in Height Safety Solutions,..

LEARN MOREEssential Height Safety are Australia’s leading Height Safety Installer and certifier of roof access systems and roof..

LEARN MOREEssential Height Safety design, install and certify roof access systems including fixed access ladders, roof walkways, roof..

LEARN MORE